When we talk about pipe stress analysis, most people imagine complex software, thick codebooks, and lots of math. But behind every successful analysis is a firm grasp of one key concept: Strength of Materials.

So, what is it? And why should a piping engineer care? Let’s break it down.

What is Strength of Materials?

At its core, strength of materials is the science of how stuff (like steel, copper, or plastic) reacts when you push, pull, twist, or heat it. Think of it like testing the limits of your favorite chocolate bar — how much bending or stretching before it snaps?

Engineers need to know these limits to ensure pipelines don’t crack under pressure (literally!).

Here are some easy-to-digest fundamentals every piping engineer should know:

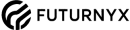

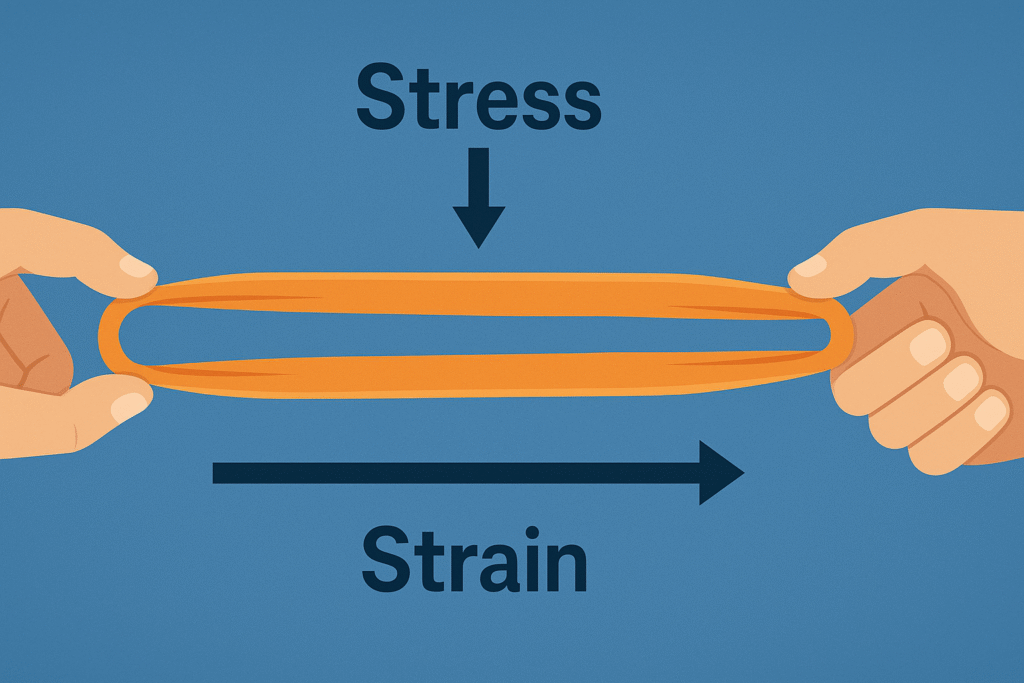

Stress & Strain – The Push and the Stretch

– Stress is the force you apply per unit area (like pushing a thumbtack into a wall).

– Strain is the resulting deformation — how much the material stretches or compresses.

Example: Pull a rubber band = stress. It stretches = strain.

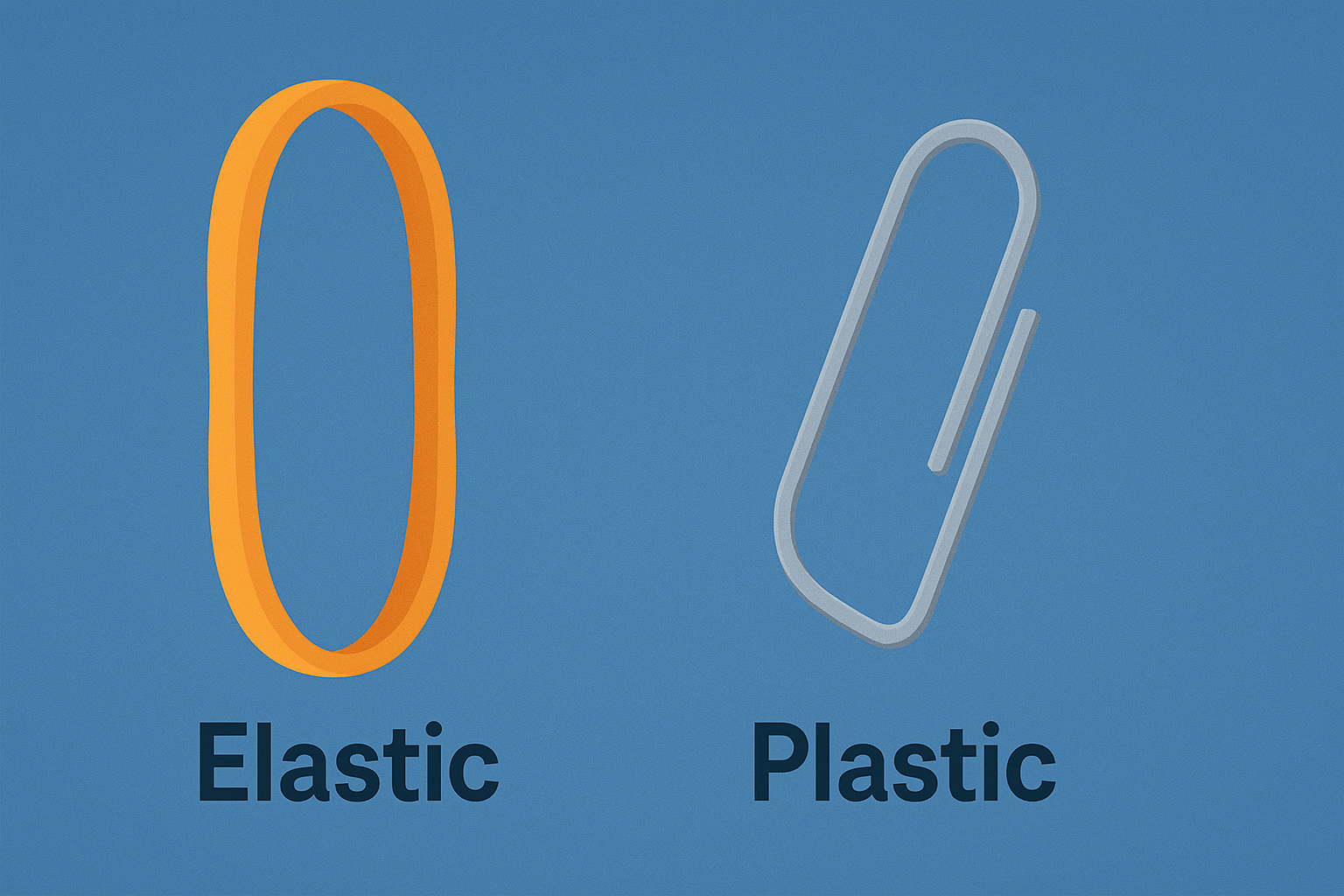

Elastic vs Plastic Behavior

– Elastic: The material bounces back to its original shape after the force is removed.

– Plastic: The material is permanently deformed — no going back.

Think of elastic like a rubber band. Plastic like a bent paperclip.

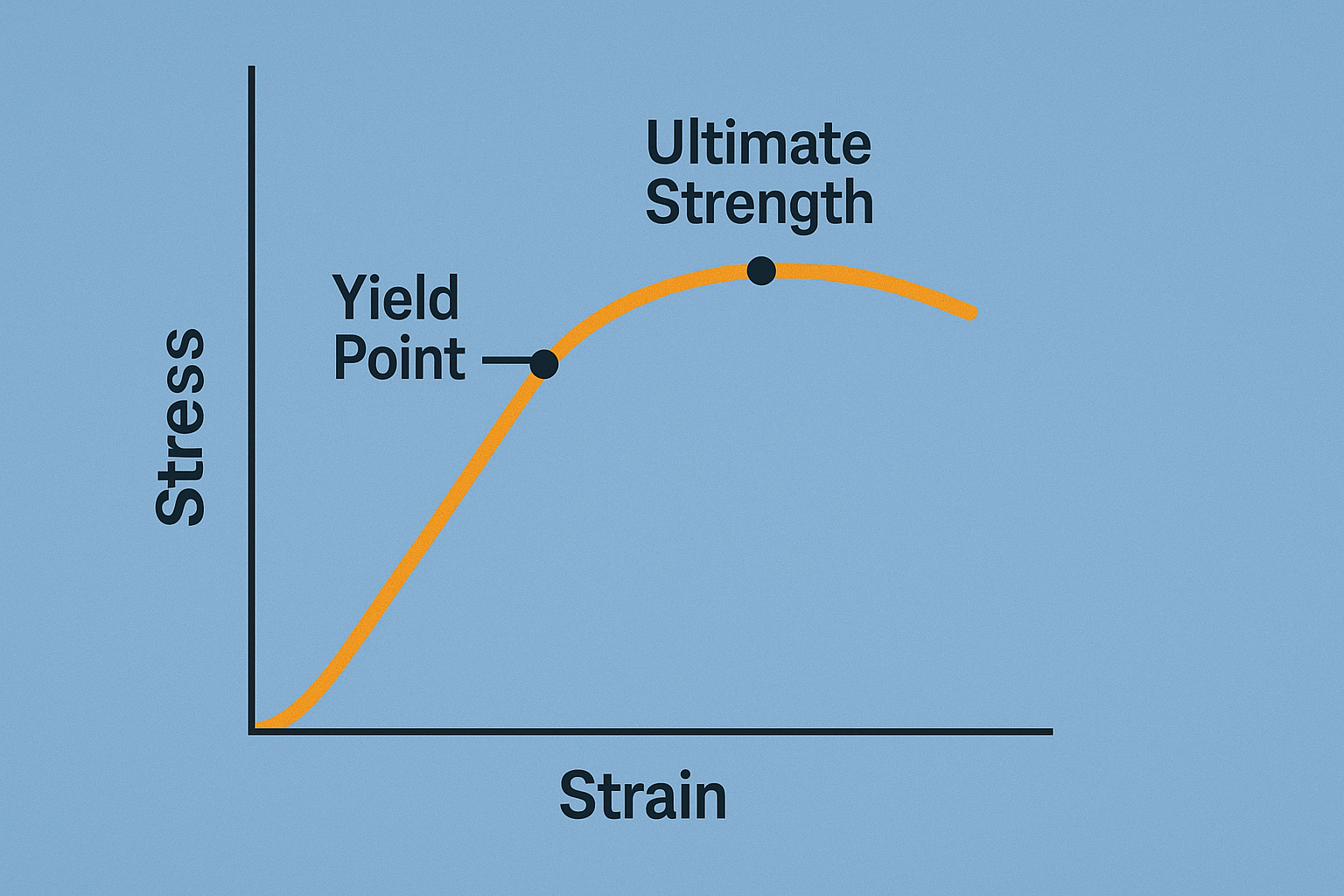

Yield Strength & Ultimate Strength

– Yield strength: The point where material starts to bend and not return.

– Ultimate strength: The maximum stress it can take before breaking.

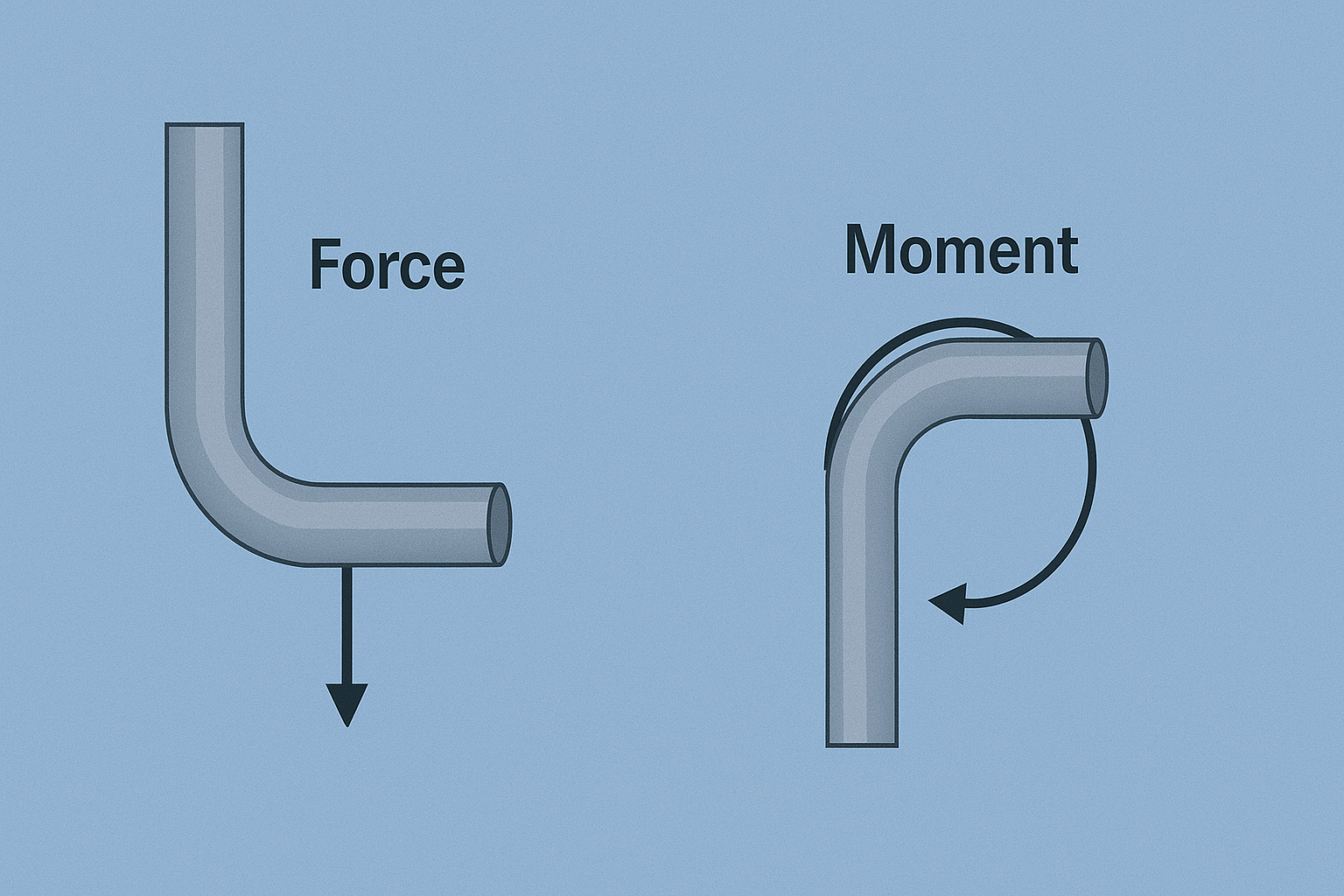

Bending and Twisting

Pipes don’t just sit still. They bend, twist, and wobble under:

– Internal pressure

– Thermal expansion

– External loads (like wind or support reaction)

We calculate:

– Bending stress (due to pipe weight or supports)

– Torsional stress (from rotation or twisting)

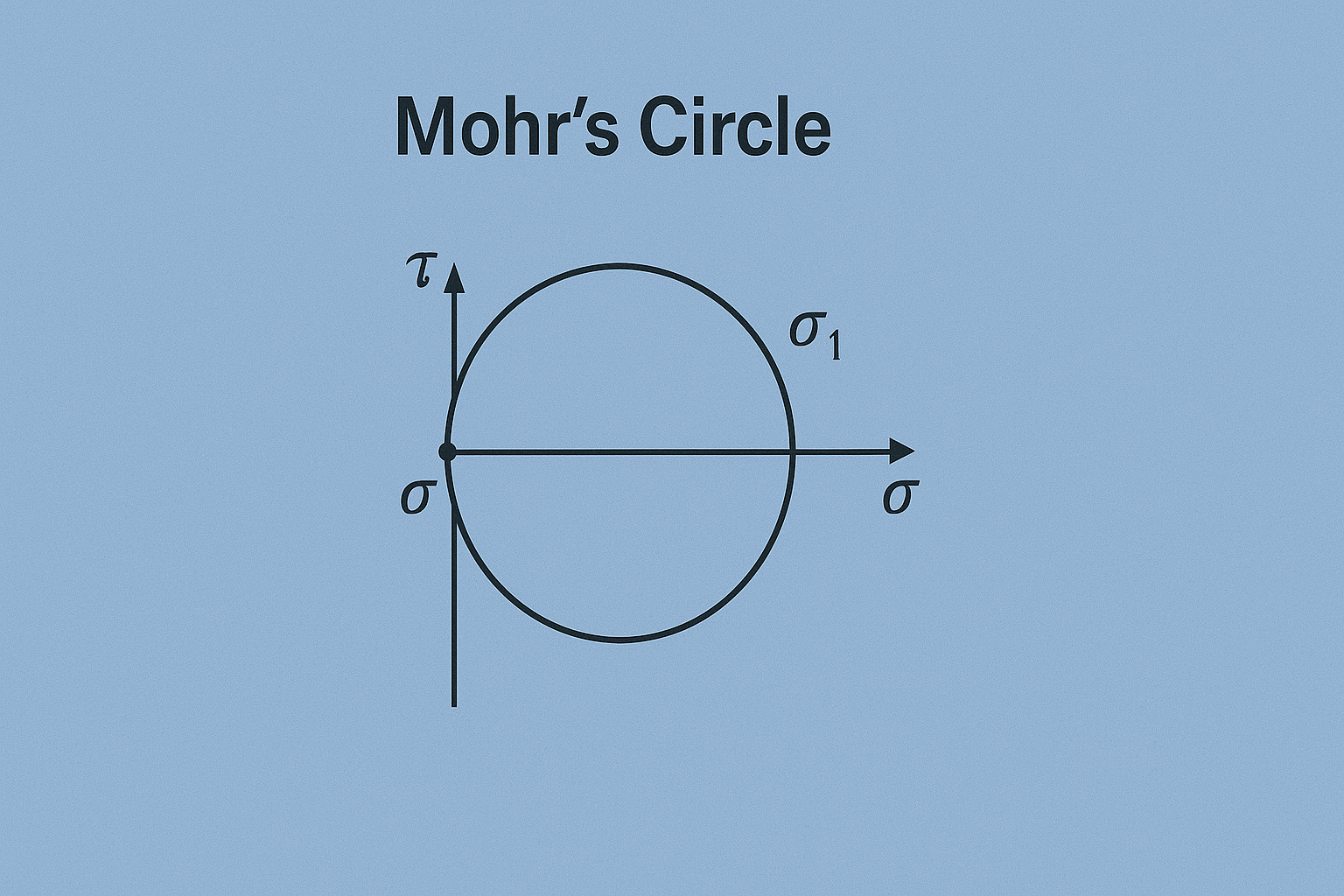

Failure Theories – Predicting the “Snap”

We can’t test every pipe to failure, so we use failure theories:

– Tresca Theory (maximum shear)

– Von Mises Theory (energy distortion)

These help engineers predict when a material will fail under combined loads.

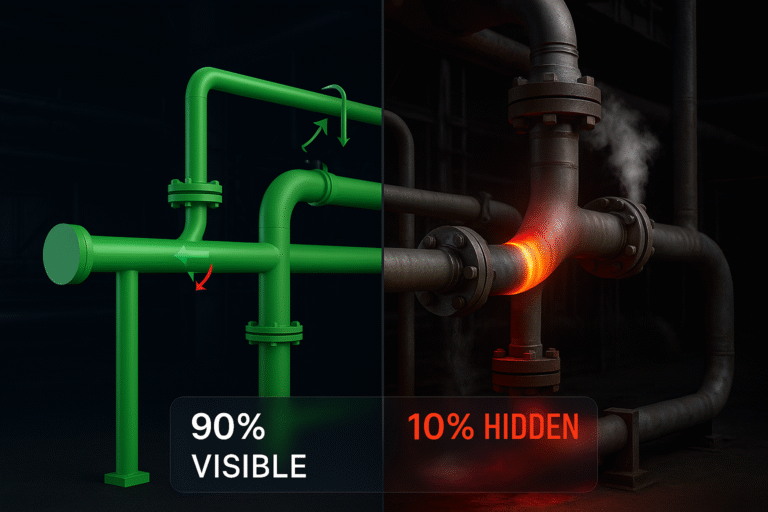

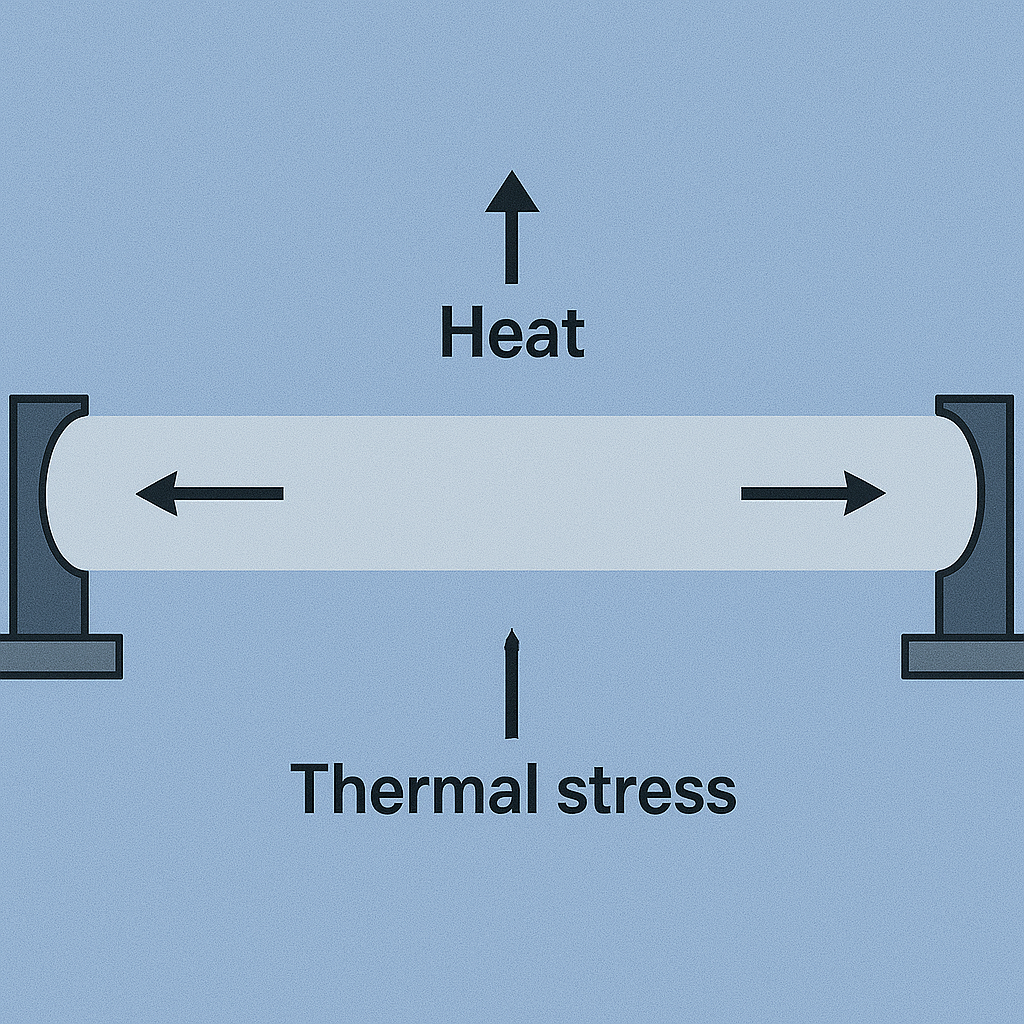

Thermal Stresses – When Heat Becomes a Problem

Ever tried opening a metal lid on a hot jar? Heat causes materials to expand. In piping systems, if expansion is restrained (e.g., fixed supports), it creates thermal stress — which can cause distortion, buckling, or fatigue.

Why Should You Care?

Because understanding these principles means:

– Your pipe designs are safer

– You can interpret stress results with confidence

– You avoid over-relying on software

– You reduce vibration, leaks, and failures

In short: It turns you from a software user to a true engineer.

As fancy as piping software has become, the backbone of good pipe stress engineering is still this: knowing how materials behave. Master the basics, and you’re already ahead of many.