In every industrial plant—whether it’s oil and gas, chemical, or power—piping systems are the veins that keep operations running smoothly. But have you ever wondered what keeps these massive networks of pipes safe and functional under extreme conditions? That’s where Pipe Stress Analysis comes in.

Pipe stress analysis is an essential part of designing safe, efficient, and long-lasting piping systems in industries like oil & gas, power plants, refineries, chemical processing, and more. At its core, this analysis ensures that a piping system can handle the stresses and forces acting on it during operation.

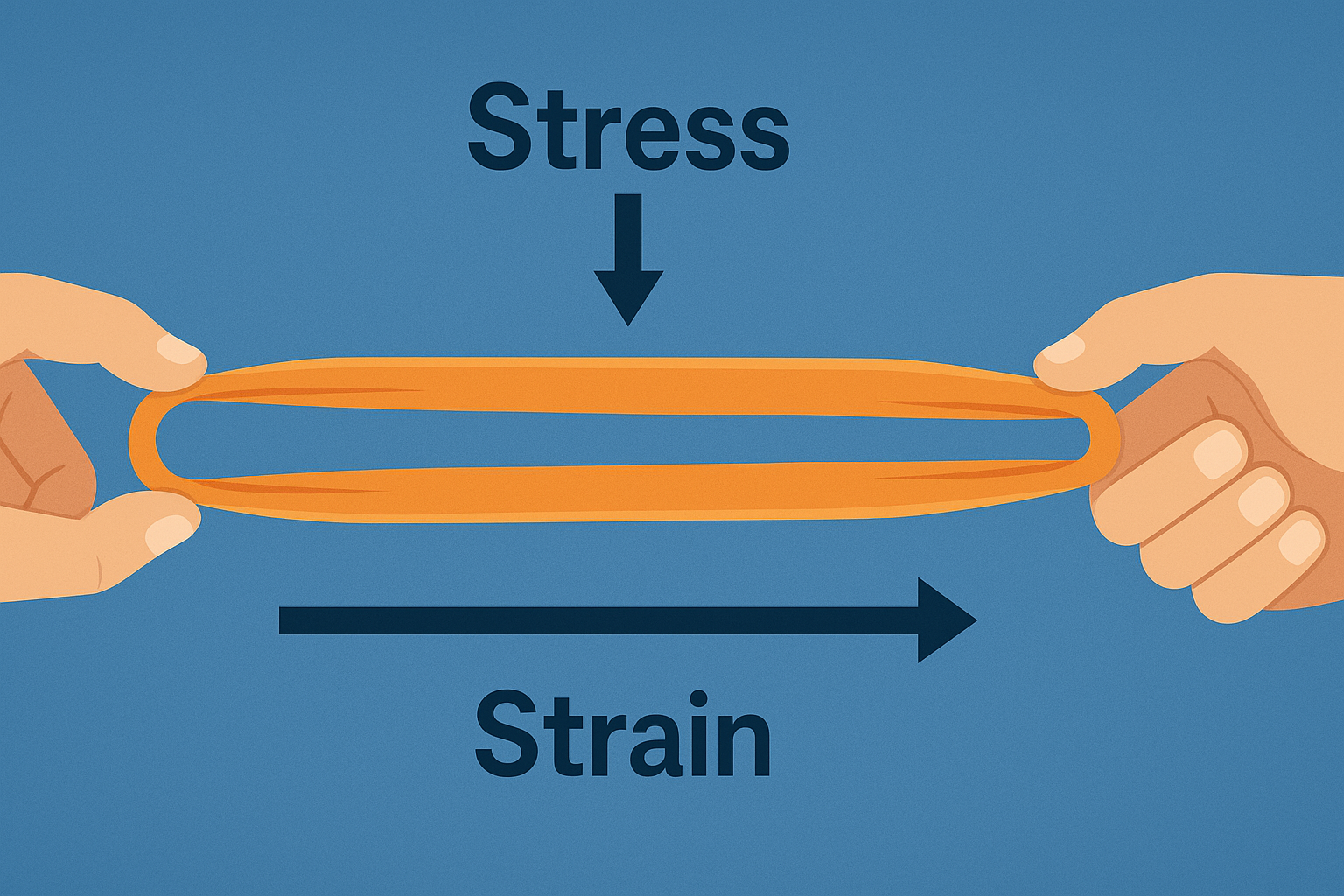

What Is Pipe Stress Analysis?

Pipe Stress Analysis is the process of evaluating a piping system to ensure it can withstand internal pressure, thermal expansion, dead weight, and environmental loads like wind or earthquakes.

It helps answer vital questions like:

- Will the pipe break due to pressure or temperature?

- Are the supports strong and correctly placed?

- Will equipment like pumps and valves be overloaded due to piping forces?

Think of it as a health check-up for the piping system.

Why Is It Important?

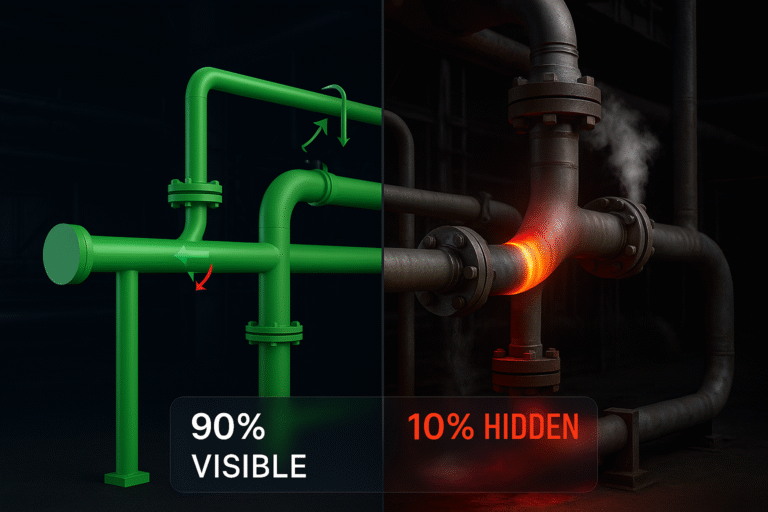

Imagine a network of pipes carrying steam, gas, or chemicals across a plant. These pipes expand, contract, vibrate, and even shake due to various loads such as pressure, temperature, and external forces. If not analyzed properly, they may crack, leak, or fail completely, causing safety hazards and costly downtime.

Pipe stress analysis helps engineers:

- Ensure the piping system meets international codes like ASME B31.3

- Avoid failures due to over-stressing

- Optimize support locations and equipment connections

- Improve system flexibility and longevity

Pipe Stress Analysis ensures the piping behaves predictably and doesn’t transfer dangerous loads to connected equipment.

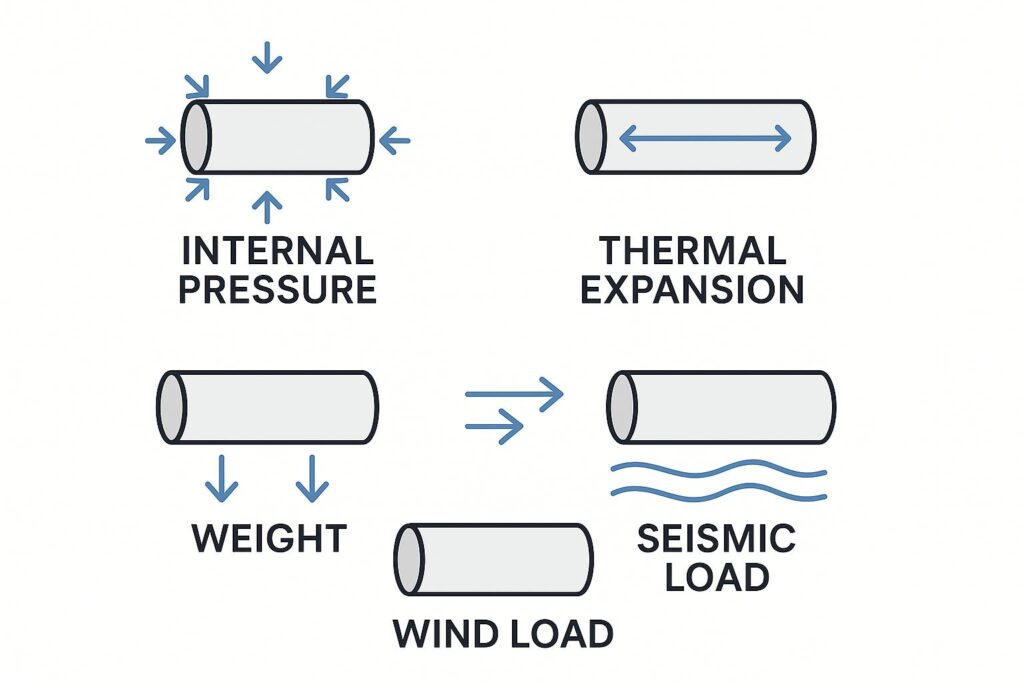

What Causes Pipe Stress?

The main sources include:

- Internal pressure

- Thermal expansion/contraction

- Dead weight of pipes and fluid

- Wind, seismic, or vibration loads

- Dynamic and occasional loads

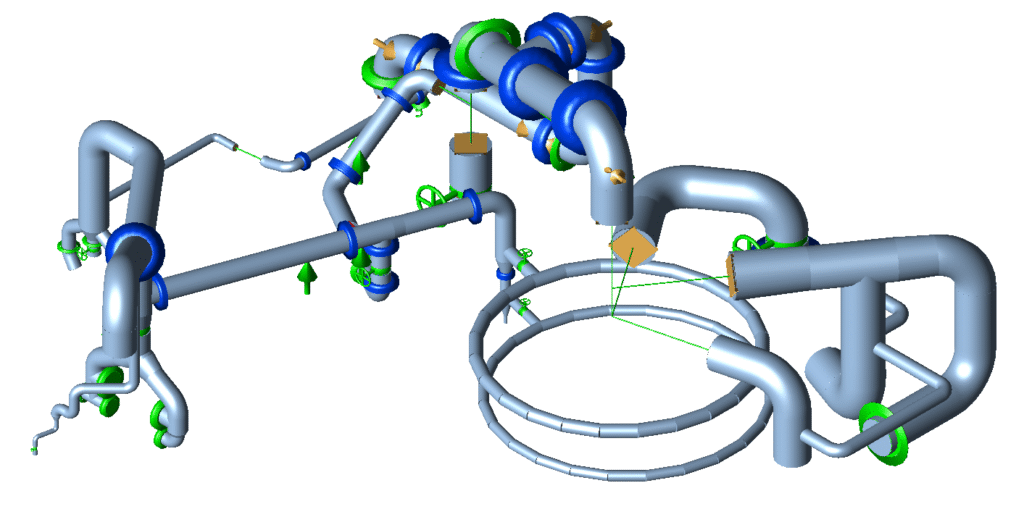

These are modeled using specialized software like CAESAR II, Rohr2, or AutoPIPE.

How Is Analysis Performed?

Engineers use specialized software like CAESAR II to model the piping system in 3D, input all loads, and simulate different conditions. The output shows where the system is overstressed or needs design adjustment.

Key Outputs of a Pipe Stress Report

- Displacement plots (movement of pipe sections)

- Stress plots and code compliance

- Support loads (forces at pipe hangers and shoes)

- Equipment nozzle loads

- Recommendations for flexible joints, anchors, and supports

Real-World Example

Imagine a hot steam pipeline stretching 100 meters. As it heats up, it expands. If fixed too tightly, it could buckle or break supports. Stress analysis helps engineers add expansion loops or spring hangers to absorb this movement.

Who Needs This?

- Design Engineers

- Project Managers

- Plant Operators

- Maintenance Teams

Pipe Stress Analysis is essential at the design stage but also valuable during modifications, expansion, or failure troubleshooting.

Final Thoughts

Pipe stress analysis is not just about calculations; it’s about building safe, cost-effective, and durable piping systems. Whether it’s a small process line or a complex power plant layout, stress analysis is a vital engineering tool to prevent failures and optimize performance.

Let’s engineer a safer future—one pipeline at a time.