In Chapter 1, we explored the fundamentals of piping design and why it’s such a vital part of industrial engineering. Now, in Chapter 2, we’re taking a step further into the core knowledge every piping engineer must have. This chapter is divided into two key parts: first, the definitions and terminology used in piping design, and second, an introduction to the codes and standards that govern how we build piping systems.

Part 1: Definitions, Terminology, and Essential Vocabulary

Piping engineering involves numerous specialized terms that are commonly used in engineering drawings, documentation, and discussions. Below are some of the most important ones every engineer should understand:

NPS (Nominal Pipe Size)

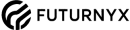

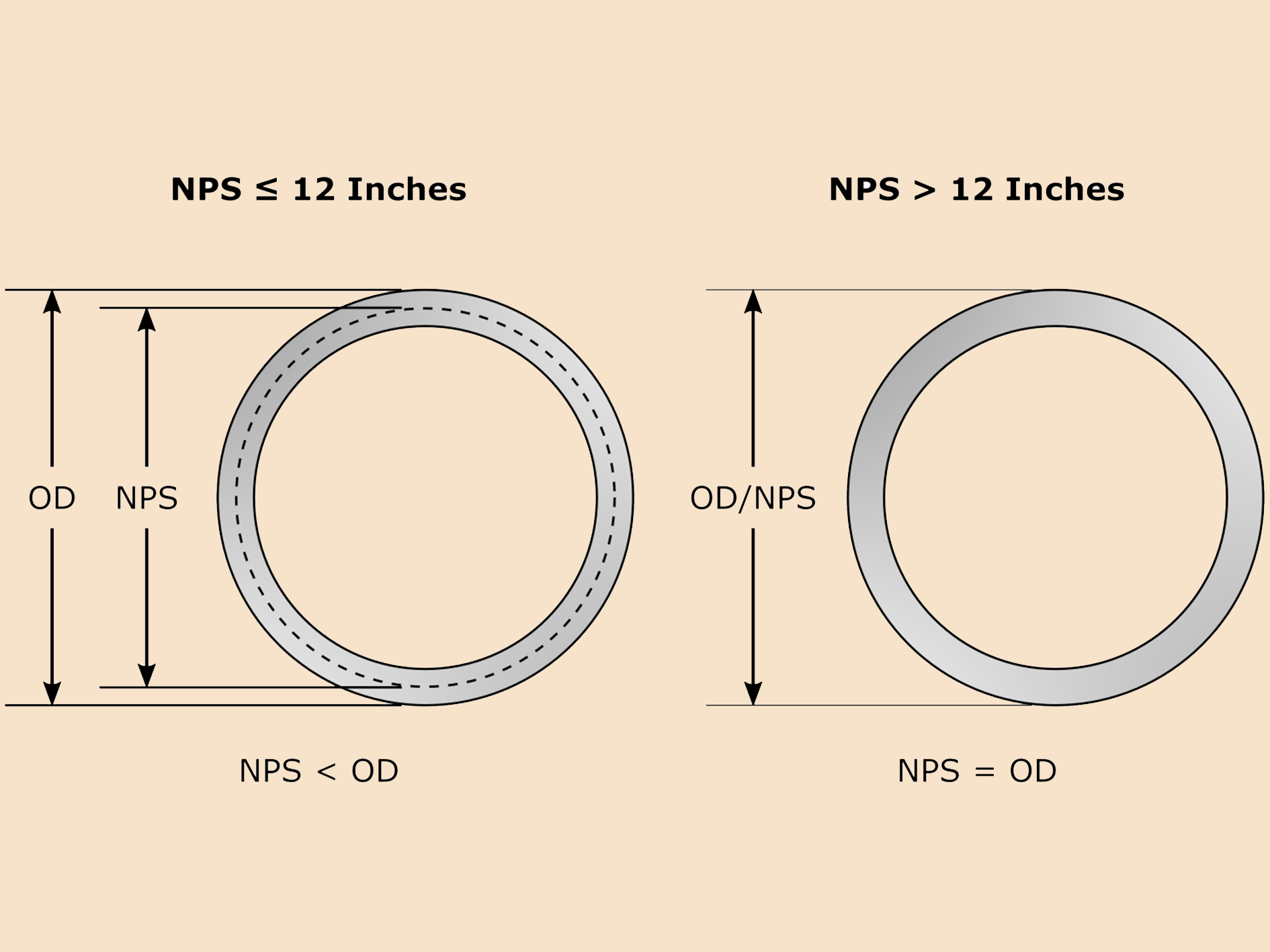

This refers to the standardized designation of pipe size used primarily in North America. It provides a convenient name for the size of the pipe, but it does not represent the actual outside or inside diameter. Nominal Pipe Size (NPS) is a dimensionless designator of pipe size. It is used to identify the nominal (approximate) inside diameter of a pipe for sizes up to 12 inches and corresponds to the outside diameter for sizes 14 inches and above.

NPS is not a measured value. It’s a label for convenience. For NPS ≤ 12 inches, the OD remains fixed while the ID varies with schedule (wall thickness). For NPS ≥ 14 inches, the NPS matches the OD in inches. Governed by standards such as ASME B36.10 (for carbon steel) and ASME B36.19 (for stainless steel).

DN (Diamètre Nominal)

DN stands for “Diamètre Nominal” in French, meaning Nominal Diameter in English. It is an international metric-based pipe size designation used mainly in Europe and countries that follow ISO or EN standards. DN is a dimensionless number used to identify the nominal internal diameter of a pipe. It does not correspond exactly to a physical measurement.

Used in ISO 6708, EN 10220, and related European/International piping standards. Commonly seen with valves, fittings, and piping specs in metric systems.

Schedule (SCH)

Defines the wall thickness of the pipe. Common schedules include SCH 40, SCH 80, etc. As the schedule increases, the wall thickness increases, which reduces the internal diameter.

ID and OD

– ID (Inside Diameter): Critical for flow calculations.

– OD (Outside Diameter): Used for pipe and fitting compatibility.

Pipe Bore Classifications

– Small Bore: ≤ 2” (50 mm)

– Large Bore: > 2” (50 mm)

This classification helps in deciding the fabrication and installation methods.

Common Abbreviations

– STD: Standard weight

– XS: Extra strong

– XXS: Double extra strong

– NB: Nominal Bore (UK/India usage)

Practical Tip:

Maintaining a uniform OD allows fittings to be standardized across varying schedules. This simplifies procurement and installation.

Why This Matters:

Understanding these terms is not just about memorization — it ensures accurate communication across teams, vendors, and construction crews. Mistakes in terminology can lead to costly errors or rework.